巨嘴鸟因遭遇野蛮行径而伤痕累累,不过得益于动物保护主义者、克难攻坚的专家团队的努力和领先的 3D 技术,这只年幼的哥斯达黎加巨嘴鸟由此成为代表坚毅和希望的民族象征。

巨嘴鸟名为 Grecia,以其所生活的地区命名,在被青少年袭击后,美丽的喙几乎失去了整个顶部部分。幸运的是,鸟在受伤后得以发现并被带到附近的 Zoo Ave 进行护理和康复,这是中美洲最大的动物救援中心。

Grecia 受到袭击一事受到了媒体的广泛关注,引发了一系列的抗议活动,并且人们提议哥斯达黎加制定更完善的动物保护法律。民众为 Grecia 的治疗募集了 10,000 美元。

如何扫描巨嘴鸟

Grecia 一事引起了哥斯达黎加圣何塞的 Grupo SG 的关注。作为 3D Systems 产品的分销商,Grupo SG 可以提供全面的 3D 解决方案,从扫描、建模到打印,帮助巨嘴鸟康复。

由 Thomas Lange 和 Karley Fu 带领的 Grupo SG 团队为此提供了技术专业知识,并将当地工业设计、牙科、纳米技术和动物学领域的专家与 3D Systems 的全球 3D 技术资源联系起来。

巨嘴鸟顶部喙的剩余部分经过一段时间硬化后,Grupo SG 使用 Artec Spider 3D 扫描仪捕获 Grecia 的喙及周围区域的尺寸和特征。在此过程中,巨嘴鸟需要保持清醒。

“在不打麻醉的情况下扫描活巨嘴鸟困难重重,”Grupo SG 的销售代表 Esteban Murillo 说,“所以我们进行了两到三次不同的扫描,以确保获取所有所需数据。巨嘴鸟一动不动,但扫描时间仍然紧迫。”

Grupo SG 为了获取更多的数据,还扫描了一只死去的巨嘴鸟的整个喙。

团队使用 3D Systems 的 Geomagic® Wrap® 软件将 3D 扫描数据处理和修改为 3D 模型。此外,其使用通常用于工业产品 3D 检测的 Geomagic Control™ 软件来获取测量和分析几何。

新喙建模

Grupo SG 与来自韩国首尔的 3D Systems 建模团队的 3D 逆向工程专家 Youngkwan Joo 分享了照片、文档、扫描文件和要求。

Joo 研究了两组数据:一组为 Grecia 的断喙扫描数据,另一组则是死去的巨嘴鸟整个喙的数据。第一步,他选择使用 3D Systems 的 Geomagic Freeform® 软件为 Grecia 设计一个合适的喙。

利用 Geomagic Freeform 用户可以将虚拟粘土模型雕刻成有机成形的精密形状。解决方案包括 Geomagic® Touch™ X 触觉式力反馈设备 – 一个具有力反馈功能的真正 3D 界面,使设计与使用真正的粘土操作一样直观。

Joo 将 Geomagic Freeform 创建的模型引入 Geomagic Design™ X,这是将 3D 扫描的面片数据转换为 CAD 模型的理想解决方案。Geomagic Design X 提供了自动式和引导式的实体模型提取,对有机 3D 扫描的准确曲面拟合,以及针对制造就绪设计的面片编辑和点云处理。

在对喙进行建模之后,Joo 设计了一个封端,用于将义喙连接到 Grecia 顶部喙的剩余部分。封端便于移除义喙时进行清洁,并且随着时间的推移 Grecia 不断长大,封端也有利于插入更大的义喙。

Joo 表示设计工作是在两个月内完成的,但实际上他花了不到十几个小时就完成了义喙的几个版本的设计与轻微修改工作。

“由于 Geomagic Design X 作为参数化建模工具的功能强大,因此极大地节省了时间。”Joo 表示,“Design X 的命令进行了优化,可以使用扫描数据轻松且快速地创建精准、优质的曲面。我们还可以为创意设计工作进行常规的 CAD 建模。”

选择合适的材料

义喙的打造离不开美国的两名 3D Systems 材料专家的共同努力 —— 西雅图大区全球材料销售和市场营销副总裁 Steve Hanna,以及 3D Systems Rock Hill, S.C. 总部的材料和工艺研发高级总监 Khalil Moussa。

Hanna 和 Moussa 研究了真正的巨嘴鸟喙的特征和哥斯达黎加专家提供的载荷因素,并就打印机和材料提出了建议。

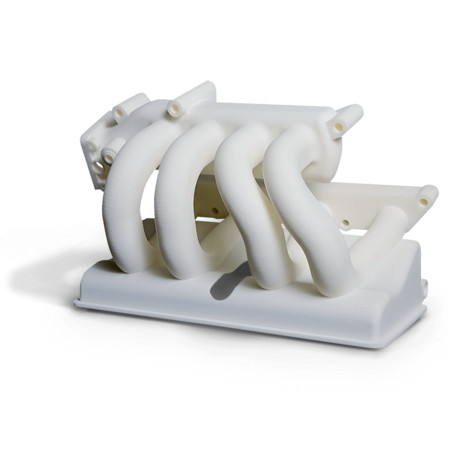

Grupo SG 和 Moussa 使用 CubePro Nylon 材料进行试验,打造了初始原型,并确定了 Duraform PA 作为最终版本。Duraform PA 是坚固耐用的尼龙材料,其强度和耐久性符合 Grecia 对于梳理羽毛和饮食的需求。

最终打印是在 Rock Hill 3D Systems ProX™ 500 选择性激光烧结 (SLS) 打印机上完成的,这款打印机以生产高精度、高耐用性和优质部件而闻名。ProX 500 和 Duraform PA 广泛用于航空部件和生物相容性医疗设备。

“重获新生”

3D 打印的封端和义喙运往哥斯达黎加供 Grecia 使用。封端通过环氧树脂胶粘合到巨嘴鸟的剩余喙部分,义喙用固定的铰链锁定在适当位置。护理团队没有将喙涂色来警示 Grecia 的悲剧和康复。

Grecia 很快适应了新的义喙。几天后,它就可以用新的义喙梳理羽毛,正常饮食。根据 Zoo Ave 的消息,它的歌唱声甚至比以往更动听。

对于 Grupo SG 来讲,义喙不仅代表了技术的进步,更是民族自豪感的象征。

“哥斯达黎加民众拯救巨嘴鸟的呼声不断高涨,我们有幸成为救助团队中的一员,为这只充满灵性的巨嘴鸟赋予新生,”Karley Fu 说,“这个由爱心人士和天赋异禀的专业人员组成的团队依托最新的 3D 技术,发起了一场前所未有的爱心行动。”