数十种 MultiJet 材料选择

ProJet® MJP 5600 MultiJet 3D 打印机解决方案可同时用 VisiJet® 系列材料打印并混合柔性和刚性光聚合物。这是在体素级别在一个部件和单一建模中逐层完成的,可实现出色的机械特性。此外,VisiJet 刚性塑料、弹性体和复合材料经过精心设计,在一个部件中具有不同程度的灵活性、材料透明度和差异化的色调。

ProJet® MJP 5600 MultiJet 3D 打印机解决方案可同时用 VisiJet® 系列材料打印并混合柔性和刚性光聚合物。这是在体素级别在一个部件和单一建模中逐层完成的,可实现出色的机械特性。此外,VisiJet 刚性塑料、弹性体和复合材料经过精心设计,在一个部件中具有不同程度的灵活性、材料透明度和差异化的色调。

了解 3D Systems 的 ProJet MJP 5600 多材料复合 3D 打印机。

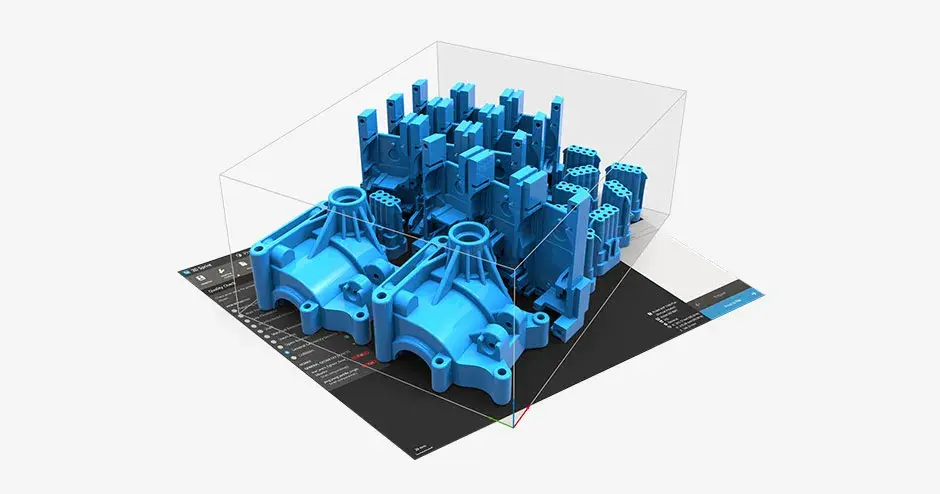

ProJet MJP 5600 提供即用型零件,打印速度比同类打印机最多快 2 倍。此多喷头 3D 打印解决方案可以快速输出完整版本,并提供一种清洁方法,由于采用自动化后处理而比其他工艺最多快 4 倍。与其他多喷头打印机相比,它具有高容量和超过 50% 的建模体积,您可以在一个建模中打印长达半米的零件 — 或多个较小的零件。

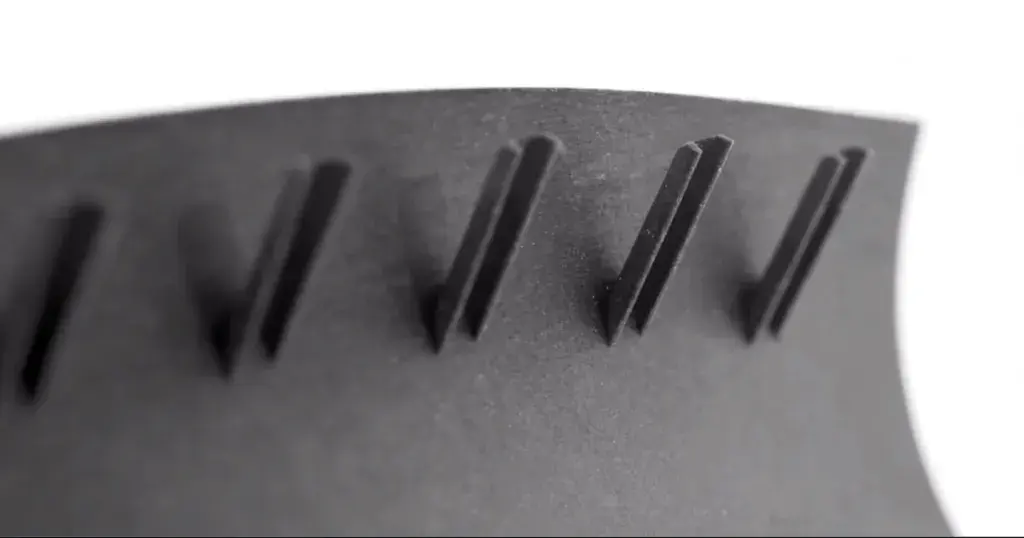

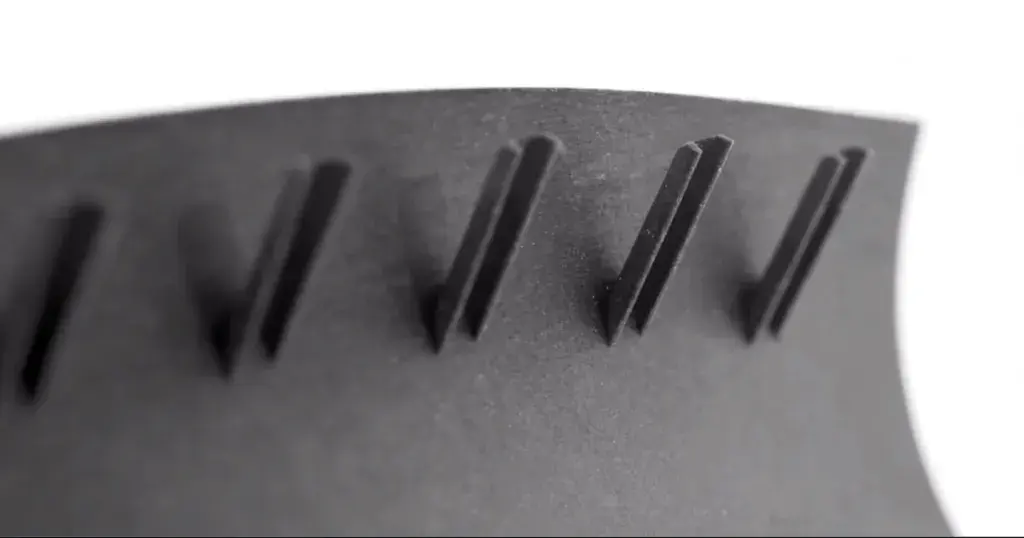

多材料原型通过混合运用透明、黑色或白色等多种材料,来传达设计理念,模拟成品

ProJet MJP 5600 提供更大的几何自由度和零件功能,以及:

使用刚性材料和弹性材料打印逼真的医学模型

ProJet MJP 5600 提供各种广泛的机械性能,是一种多材料复合打印机,可为各种应用生成十分逼真的功能原型和模型。此多喷头打印机输出各种尺寸,可生产包覆成型部件、多材料组件、类橡胶部件、夹具和固定装置、模具等。

ProJet MJP 5600 的打印速度比同类 PolyJet 打印机最多快两倍。此外,凭借更大的建模体积,可以利用 ProJet MJP 5600 的功能,与竞争对手的多材料 3D 打印机相比,可将部件成本降低多达 40%。*

* 与 Stratasys 的 Objet350 Connex3™ 和 Objet500 Connex3™ 相比

高质量、高速度且易于使用的多喷头打印

有助于提高 SLA 质量和精度的中端集成式解决方案