生产级 SLS 工作流程解决方案

SLS 380 是一种具有高吞吐量的 SLS 增材制造解决方案,可实现前所未有的吞吐量、一致性、性能和产量。针对想要将增材制造融入到工厂车间生态系统的需求,3D Systems 的 SLS 380 及其补充软件、材料处理和后处理解决方案进行了优化,能够以经济实惠的方式批量生产部件。

SLS 380 是一种具有高吞吐量的 SLS 增材制造解决方案,可实现前所未有的吞吐量、一致性、性能和产量。针对想要将增材制造融入到工厂车间生态系统的需求,3D Systems 的 SLS 380 及其补充软件、材料处理和后处理解决方案进行了优化,能够以经济实惠的方式批量生产部件。

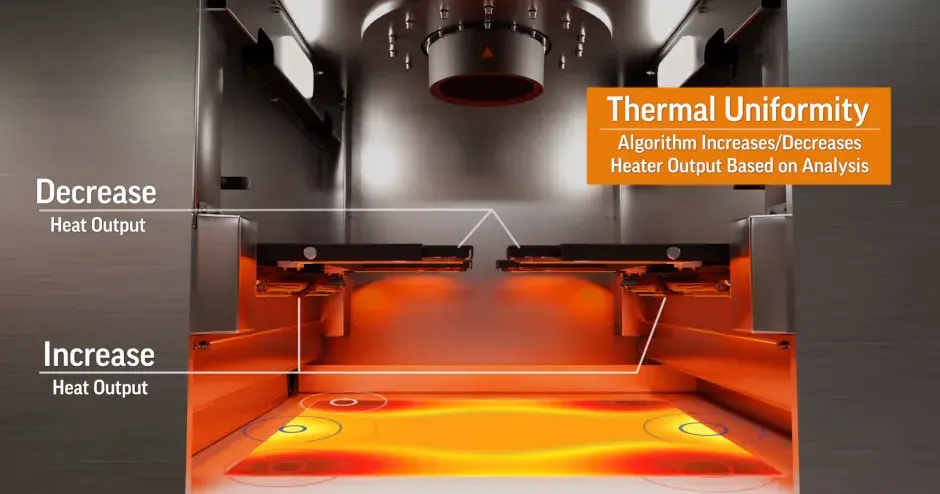

SLS 380 具有闭环流程控制功能,可在多个部件、建模、打印机和打印场所之间实现较高的可重复性。除了新的水冷激光器,该系统还采用了定制开发的 3D Systems 算法,可实时管理、监控和控制建模室内的热均匀性。

该算法管理八个单独校准的加热器,以及一个每秒可捕获超过 100,000 个建模室内热数据样本的集成式高分辨率 IR 摄像头。这些数据与 IR 传感器相结合,在构建过程中共同保持各部件构建层的热均匀性。通过在构建过程中保持更加一致的热均匀性,制造商可交付尺寸更稳定、机械性能更好、可重复性更高和产量更高的部件;所有这些都将减少人为干预并降低总体运营成本。

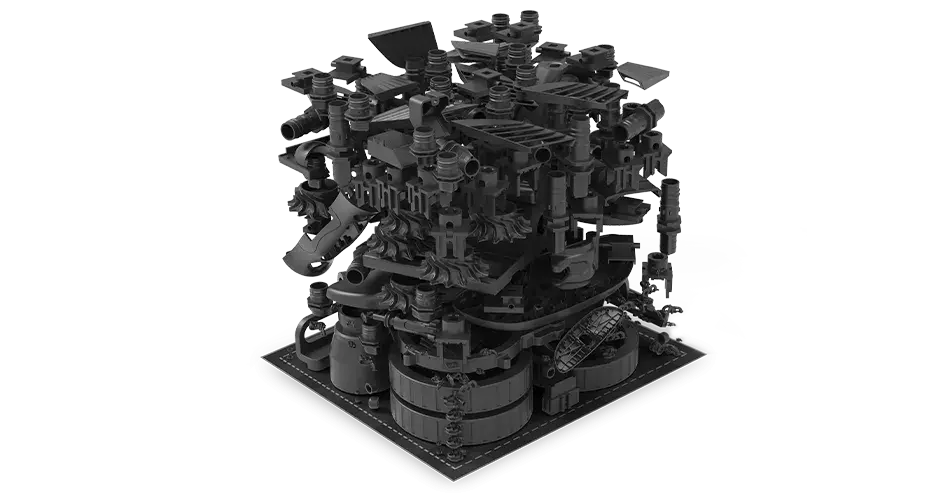

SLS 解决方案最重要的功能之一是材料质量中心 (MQC),其能以最佳的新鲜和回收粉末比例,按需控制、混合和供给材料。SLS 打印机有两种 MQC 可供选择:MQC Single 和 MQC Flex。MQC Single 可连接一台 SLS 打印机,而 MQC Flex 经过优化,可最多同时向四台打印机供料,最大限度减少材料浪费和操作员干预。MQC Flex 可根据具体混合比自动混合新鲜和回收粉末,其配备的粉末回收仓可十分便捷、及时地存储打印后未使用的粉末。两个版本的 MQC 都具有全自动送料功能和用于后处理的集成式拆分站。

SLS 材料缸

支持在一台打印机上使用多种材料。快速轻松更换材料,大幅提升使用价值,扩展 SLS 打印机的应用范围。有无 MQC 模块均可使用。兼容 SLS 380 和部分传统打印机。

SLS 380 采用先进的单一界面软件 3D Sprint 进行文件准备、编辑、打印和管理。该软件可快速高效地将设计文件转变为忠实于 CAD 文件的优质打印部件,而无需其他第三方软件。3D Sprint 针对生产环境进行了优化,提供省时的工作流程、直观的用户界面和用户体验,实现打印机容量最大化并提高建模体积利用率,以便批量执行作业。

全新的 SLS 380 3D 打印机经过优化,可满足对经济实惠的批量部件生产的需求,其配备软件、材料处理和后处理解决方案,将工厂级部件可重复性和可扩展性提升到新高度。

生产级尼龙材料、先进的软件工作流程和新的选择性激光烧结技术,共同为直接 3D 生产提供了高效的解决方案。

SLS 380 提供一流的部件质量、快速构建速度、自动化生产工具,而且运行总成本低于同类打印机。

选用一系列生产级品质的尼龙材料生产出坚固、耐用的部件。可选的材料包括抗冲击、耐疲劳的韧性 Nylon 11 材料,或坚固、医疗级或可阻燃的 Nylon 12 热塑塑料和填充尼龙。

用户友好的高级 SLS 技术