客户支持文档

查找安全数据表、用户手册、订购耗材等

达到 UL94 V0 阻燃等级的黑色塑料,其热变形温度 > 150℃

Figure 4® High Temp 150°C FR Black is a rigid, flame-retardant black material that can be used for production parts requiring UL94 V0 rating as well as FAR 25.853 and 23.853 capability. It provides long-term environmental stability with an injection molded-like surface quality.

This material is recommended for consumer, transportation, and aerospace applications that require performance at high temperatures like brackets, covers, and circuit board housings and covers.

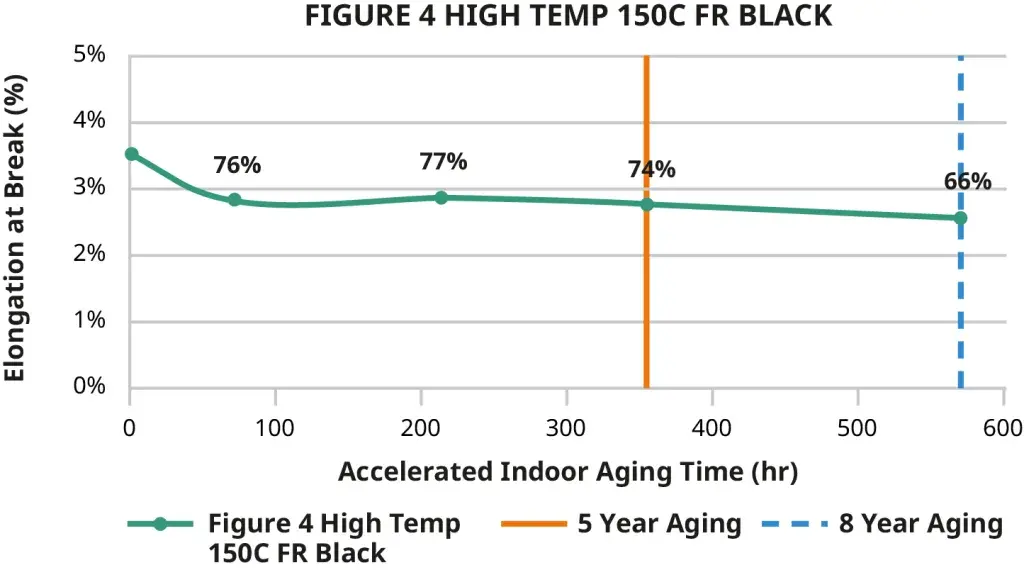

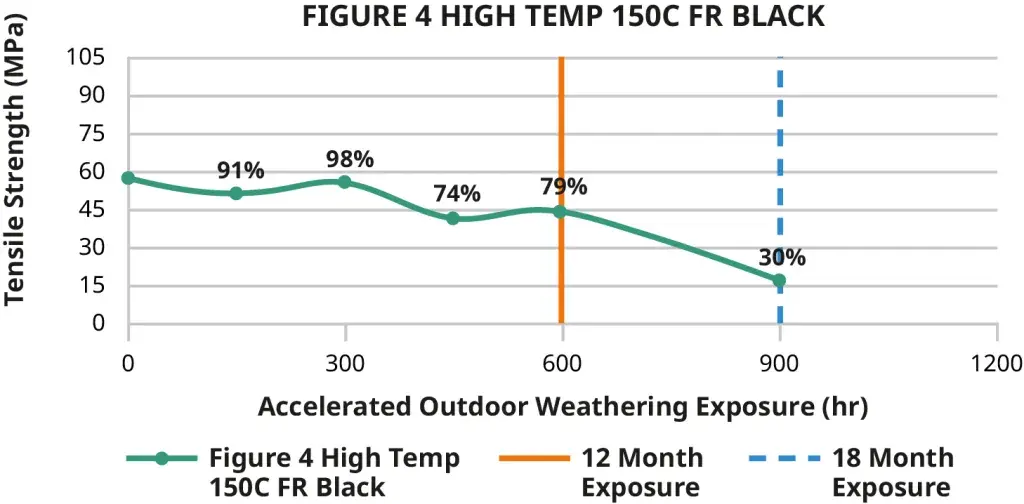

Figure 4 High Temp 150°C FR Black is tested to 8 years of indoor and 1.5 years outdoor mechanical performance per ASTM D4329 and ASTM G194 methods, ensuring that printed parts remain functional and stable for long periods in real-world conditions.

The full suite of mechanical properties is given per ASTM and ISO standards where applicable. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Material properties include physical and mechanical properties and thermal, UL flammability, and electrical (dielectric strength, dielectric constant, dissipation factor, and volume resistivity).

Figure 4 technology prints parts that are isotropic in mechanical properties meaning the parts printed along either the XYZ axis will give similar results. Parts do not need to be oriented to get the highest mechanical properties, improving the degree of freedom for part orientation for mechanical properties.

Figure 4 High Temp 150°C FR Black is engineered to give long-term environmental UV and humidity stability and long-lasting black color. This material has been tested for its ability to retain a high percentage of its initial mechanical properties over a period of time. This test data provides real performance conditions to consider for the application or part.

The charts show a sampling of the dataset. The full datasheet includes indoor and outdoor stability data for tensile strength, elongation at break, tensile modulus, and impact strength. The actual data value is on the Y-axis, and data points are a % of the initial value.

Tested per ASTM D4329 standard method.

Tested per ASTM G194 standard method.

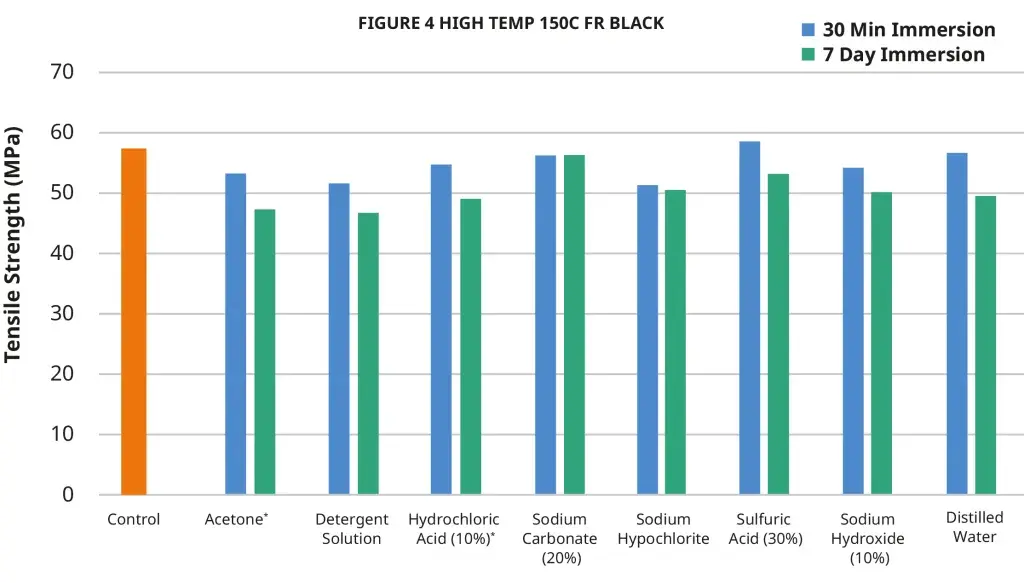

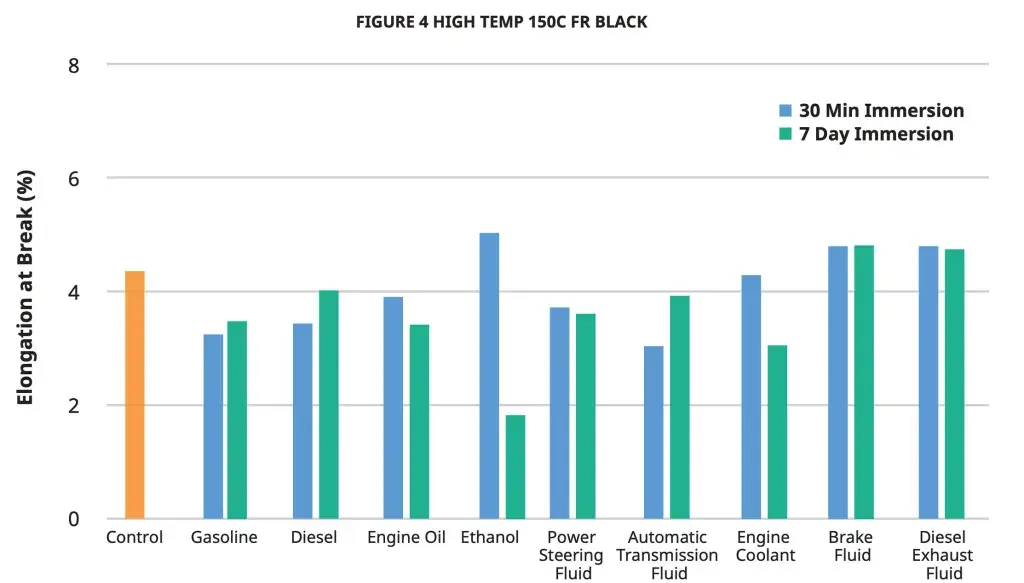

Hydrocarbons and cleaning chemical compatibility can be critical to application compatibility. Figure 4 High Temp 150°C FR Black parts were tested for sealed and surface contact compatibility per ASTM D543 test conditions and per USCAR2 test conditions. The full data sheet includes additional data tables for tensile strength, tensile modulus, and elongation at break.

* Note: Not all products and materials are available in all countries – please consult your local sales representative for availability.

用于生产部件的生产级刚性材料

HDT 超过 300 °C 的耐高温半透明材料

具有高稳定性的柔性耐用塑料

业界首个可用于直接 3D 生产的可定制、全集成式工厂解决方案

可扩展的半自动化 3D 制造解决方案,可随业务增长而扩展

超快速且经济实惠,适用于当天完成原型制作和小批量生产

高速、高精度、可重复精度,实现无工具制造

查找安全数据表、用户手册、订购耗材等