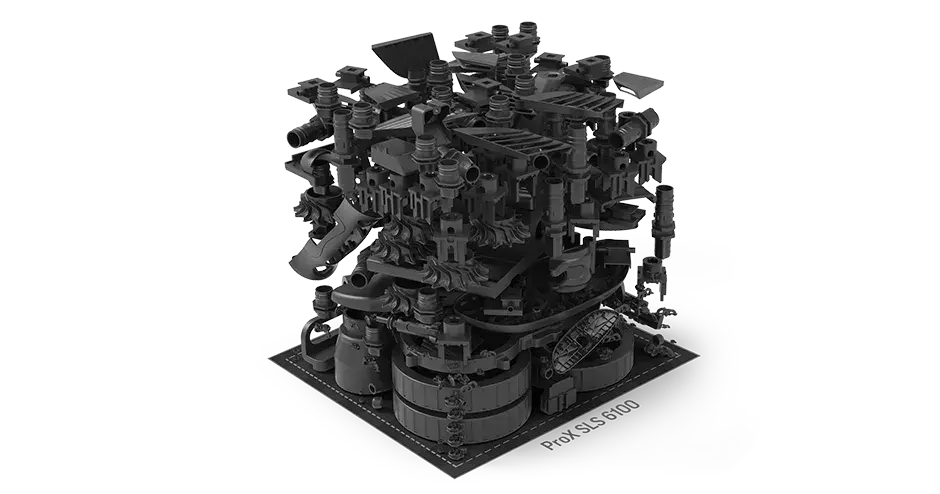

SLS 打印机使用 3D Sprint® 软件,这是用于塑料打印的一体化软件,能提高 SLS 生产的生产力和质量,无需使用其他第三方软件。3D Sprint 提供了多种工具用于准备和优化 CAD 数据并管理打印流程,包括高密度自动 3D 嵌套、用于预构建验证的质量检查、修复选项、用于高效构建计划的打印队列工具、用于小部件外壳的骨架结构生成器等。无论是中型框架还是大型框架,我们都能提供有着不同建模体积、自动化水平和广泛材料选择的 SLS 打印机产品。

了解 SLS 打印流程

选择性激光烧结技术 (SLS)是一种基于粉末的 3D 打印技术,可使用激光将材料层融合到最终部件中。激光跟踪 3D 设计每个横截面的图案,并将其复制到粉末床上。构建完一层后,建模平台便会下降,并在上一层之上开始构建另一层。此过程将持续到构建完所有层,才真正完成部件制造。

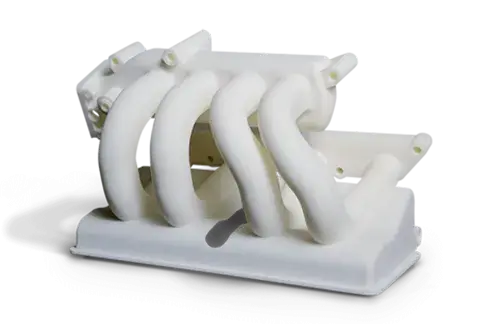

SLS 是一系列功能应用的首选技术,包括卡扣连接、活动铰链和其他机械接头。SLS 可用的材料种类和平台尺寸也使该工艺成为要求强度和耐热性的产品的直接制造的理想选择。

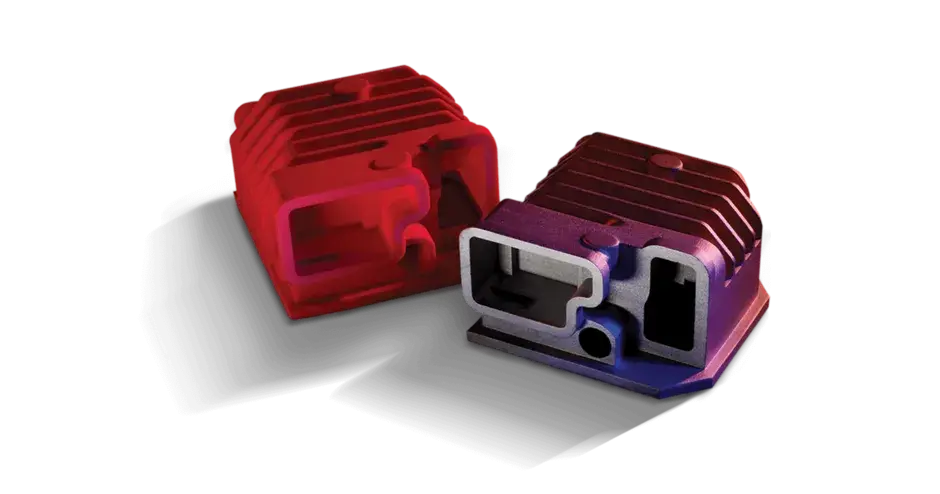

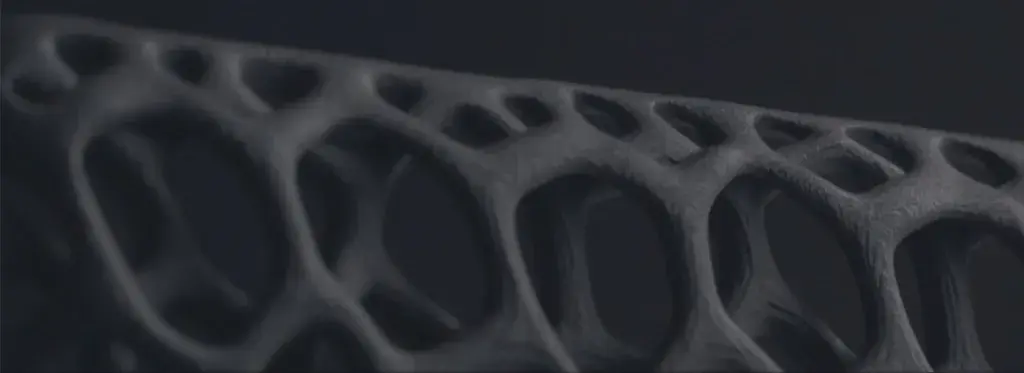

SLS 的一个主要优点是,它是自支撑增材制造技术。由于产品在制造时位于粉末床中,因此不需要额外的支撑结构,这使 SLS 能够制造出其他技术无法制造的几何形状。SLS 的自支撑特性也意味着无需移除支撑结构,从而实现复杂的内部组件和一体式组件。

当需要耐用的塑料部件时,SLS 便能充分显示其优势。SLS 部件以其坚固耐用著称,可与使用传统注塑成型等方法生产出的部件相媲美。SLS 广泛应用于汽车和航天等行业的各类最终用途应用。

对于原本需要经过传统制造装配的小型零部件,依靠 SLS 的坚固耐用性及其生产高度复杂零部件的能力,可以节省大量时间和成本。SLS 实现了功能、强度和复杂度的完美结合。由于摆脱了昂贵又低效的开模或换模过程,SLS 能更有效地生产大量定制的小体积最终用途部件。这项技术也能够消减部件的生产数量,因为 SLS 部件有着更高的耐用性和对环境的适应性。正如其他增材制造技术,SLS 使用数字化存储来储存部件和模具,使用的数据永远不会锈蚀,也不会在运输过程中丢失,而且不需要高昂的储存成本。设计结果总是可以在需要时随时获得并立即开始生产,即使无原件可用。

从抗冲击塑料到用于石膏和金属铸件的苯乙烯基材料,可用于 SLS 的材料使用范围非常广泛。SLS 常常用于制造外罩、卡扣连接部件、汽车模具和薄壁管道等中小批量生产的最终用途部件。一些 SLS 工程塑料由阻燃材料制成,能满足飞机和消费品需求。我们还提供刚性强、热阻性好的玻璃填充材料,以及具有极高刚度的纤维增强塑料。SLS 还提供另一方面的材料选择,制造类橡胶的柔性部件,可用于如软管、垫圈、手柄衬垫等应用。

可替代传统注塑成型制品的高强度聚酰胺 12 热塑塑料;包括达到食品级、医疗级和阻燃性要求的选项。

专为获得更佳的最终用途部件性能而设计,这些材料由玻璃、铝或矿物纤维填料制作而成,在刚度、耐高温、强度和表面光洁度方面具有诸多先进的属性。

可在恶劣环境中提供铸型部件性能的抗冲击聚酰胺 11 热塑塑料;由于具备可以迅速恢复原状的弹性,因此是制造卡扣连接和活动铰链的理想之选。

具备类橡胶的柔韧性,适合具有卓越弹性记忆力、抗撕裂性和耐磨性的原型及生产部件。

适合原型金属铸件的损耗模型和中低批量生产运行,无需使用模具。

SLS 打印机使用 3D Sprint® 软件,这是用于塑料打印的一体化软件,能提高 SLS 生产的生产力和质量,无需使用其他第三方软件。3D Sprint 提供了多种工具用于准备和优化 CAD 数据并管理打印流程,包括高密度自动 3D 嵌套、用于预构建验证的质量检查、修复选项、用于高效构建计划的打印队列工具、用于小部件外壳的骨架结构生成器等。无论是中型框架还是大型框架,我们都能提供有着不同建模体积、自动化水平和广泛材料选择的 SLS 打印机产品。

使用 3D Sprint 自动对 198 个部件进行放置和嵌套的 SLS 建模平台

SLS 380

381 x 330x 460 毫米(15 x 13x 18 英寸)的建模体积

sPro 140

550 x 550 x 460 毫米(22 x 22 x 18 英寸)的建模体积

sPro 230

550 x 550 x 750 毫米(22 x 22 x 30 英寸)的建模体积

适用于选择性激光烧结技术的工业级流程控制增材制造解决方案

SLS 技术可生产坚固耐用的部件,十分适合高性能原型制造和最终用途应用。3D Systems 的 DuraForm® SLS 材料经过优化、验证和测试以确保品质,具有一致的 3D 机械属性。

3D Systems 与其他同类产品的拉伸与抗冲击测试结果对比

大型 SLS 建模能力,加上快速的建模时间、高密度嵌套和无支撑结构,可助您最大程度以更快的速度打印更多部件。

以其他方式无法生产 SLS 交付的产品

逐一对比测试结果表明,3D Systems 的 SLS 打印机可提供一流的部件质量。*3D Systems 的 SLS 解决方案可提供卓越的精度、部件分辨率、边缘清晰度和表面光洁度。

* ProX SLS 6100 利用 DuraForm ProX PA 所打印的部件文件与同类竞争产品利用 PA 12 打印相同部件文件对比

3D Systems 的 SLS 可提供光滑的表面、精密细节的高分辨率和锐边

利用真正可满足您应用需求的尼龙材料进行制造。无论您是需要坚固、耐热、阻燃、灵活的材料,还是食品级和医疗级材料,3D Systems SLS 材料组合都能满足您的需求。

了解 SLS 增材制造材料如何应用于您的业务

作为一种自支撑的建模方法,SLS 可以生产无法通过其他方式制造的复杂几何图形,如一体式设计、轻量组件和大规模定制产品。

提高性能并加快复杂功能性尼龙部件的生产

相较于类似打印机,3D Systems 的 SLS 的特征和功能可降低高达 20% 的运营成本。自动化生产工具、高吞吐量、材料利用率和可重复性,这些只是所带来优势的一部分示例。

利用生物相容性材料进行小批量生产和大规模定制,以实现患者专用医疗设备等应用